2500+

Successful Projects

The race to win customers’ trust and huge market share has pushed businesses to enhance their supply chains and improve logistics to ensure the safe and fast delivery of products. However, supply chain visibility remains the most significant challenge for logistics businesses in meeting their current market demands. In such a situation, a logistics management system has turned out to be a savior by helping companies manage their supply chain operations, providing visibility to all parties, and coordinating the delivery of products.

A logistics management system saves businesses from the hassle of manual order handling and also streamlines business operations, ultimately saving you expenses. While the pandemic has pushed for the wide adoption of logistics management systems, its current market insights show no sign of slowing down.

Table of Contents

Confined to the Logistics Management System? Not Yet! Worry not; keep reading this guide to logistics management systems to understand their benefits, components, challenges, and development requirements.

The logistics management system is a set of software and tools responsible for the strategic planning and execution of storing and delivering goods and services to customers. A typical logistics management system oversees various aspects, such as inbound and outbound transportation, warehouse operations, fleet supervision, order processing, inventory oversight, collaboration with third-party logistics providers, and supply-demand forecasting.

It includes almost every vital supply chain activity, from product launch to market introduction, including production scheduling, sourcing, procurement, packaging, and distribution. It also helps identify the most effective means to deliver goods and services to the final consumer.

Logistics Management Software (LMS) streamlines logistics operations by enhancing the production cycle and facilitating quick access to crucial information. It assists businesses in overseeing the diverse processes in the production cycle, from the delivery of raw materials to the distribution of finished products to consumers.

The scope and functionality of the logistics system have expanded to accommodate a wide range of operations and processes. It is somewhat similar to supply chain management software (SCMS), which includes tools for managing transactions, processes, and suppliers. The capabilities of logistics management system extend to areas such as:

Logistics management software can eliminate traditional paperwork and spreadsheets, simplifying management. As a result, logistics becomes more streamlined and efficient, transforming the management of materials, goods, freight, sales orders, inventory, and production.

Businesses with an internal logistics or supply chain department and third-party logistics providers can use the different modules (listed below) of this system based on their needs to manage their logistics and supply chain operations effectively.

A complete Logistics management system is a collection of various components and modules responsible for handling different logistics management activities. These systems help businesses manage the supply chain in various ways.

Here’s a complete list of key components and modules of a logistics management software system structure:

This software suite helps businesses track and manage product stock information. It monitors product movement and stock levels and offers data and analytics. The inventory management system of logistics software provides key insights into inventories and helps businesses make decisions like when to restock, how many quantities to order, and where to store them.

The warehouse manager system allows businesses to maintain, control, and automate the operations related to warehousing. It is a set of tools and processes that helps streamline the management of products, from storing them in the warehouse to dispatching them to customers to tracking them.

The system allows managing everything from the point of receiving orders and processing payments to the execution of those orders. This includes detecting fraudulent activities and handling necessary documentation for suppliers, storage facilities, and shipping procedures.

An order management system is a tool that businesses use to streamline these processes by automating order receipt and fulfillment and synchronizing data from various activities into a unified interface.

Transportation is undoubtedly the core of logistics, enabling businesses to move their products from one location to another. While some companies might use standalone solutions like a trucking management system to oversee their fleet, a more comprehensive approach would be to use a transportation management system.

This system can manage the entire fleet and handle other transportation-related processes, offering a more advantageous solution.

This involves the tasks required to oversee and track the delivery of goods. Companies require reliable and user-friendly freight management systems for efficient delivery management.

These systems are capable of managing a range of operations, from handling documentation and compliance to optimizing routes and tracking freight. They can also provide data and analytical reports to aid in the development of more effective freight management strategies.

The process of managing return orders can be disorderly. However, an efficient reverse logistics management system can make this process more orderly. Such a system manages data related to returns and provides updates on the status of return activities, keeping you informed at all times.

Sometimes, even a minor human error may lead to huge losses, particularly in the field of logistics, where operations are conducted on a grand scale.

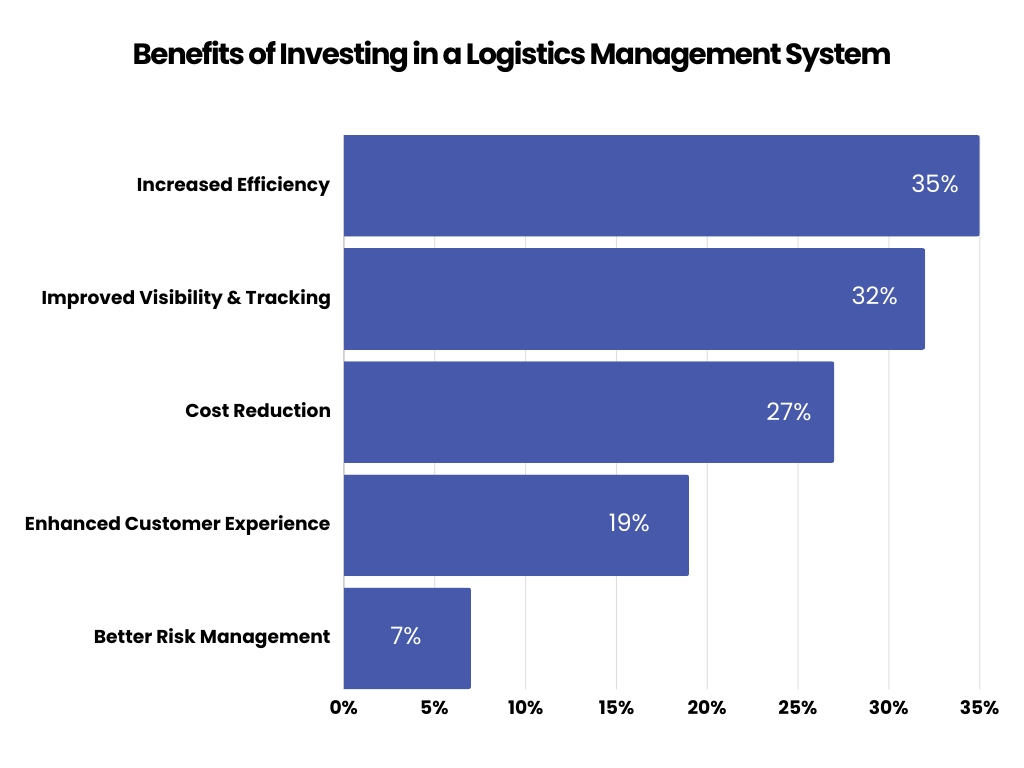

Therefore, a logistics management system is essential to maintain order and ensure smooth operations. Here are some of the main advantages of such a system:

Through automated logistics management, businesses can gain a comprehensive understanding of their operations. This enhances customer relationships and reduces the need for excess inventory, leading to an improved order fulfillment rate and increased profitability.

Logistics management systems primarily focus on boosting operational efficiency without compromising profit margins. Implementing a logistics management system can eliminate resource waste, meet quality standards, and minimize failures, deviations, and defects.

Logistics management solutions assist in analyzing past data to optimize routes, which reduces fuel usage and improves asset utilization. This results in reduced operational costs and increased organizational efficiency.

Companies that invest in creating a logistics management system can offer superior customer service and a smooth shipping process. This leads to an improved customer experience, fostering brand loyalty and enhancing the company's reputation.

The logistics management system involves data analytics, enabling the company to glean valuable insights and respond more effectively to customer requirements. It also offers a 60% increase in process execution visibility, thereby boosting the company's operational efficiency by 30%.

Intermodal operations involve transporting freight using two or more different transport modes to deliver it from the source to the customer.

A logistics management system uses standardized containers to mitigate the risks associated with intermodal operations, thereby reducing costs and improving transportation reliability, safety, and eco-friendliness.

The development of a logistics management system incorporates an intelligent route planning tool. This tool allows companies to select the most efficient routes for delivering their products, helping to minimize empty miles, avoid traffic jams, and ensure timely delivery to customers.

The global logistics sector is expanding exponentially, offering a range of opportunities and challenges. The pandemic has necessitated a greater reliance on a logistics management system for businesses to keep up with evolving demands and deliver essential goods to consumers.

The logistics management systems are here to solve a long list of challenges that include:

The surge in fuel prices significantly raises the cost of goods transportation. The logistics sector faces the daunting task of keeping shipping costs low for product delivery to customers. The route optimization feature in logistics software can help the logistics sector navigate this tumultuous challenge.

With proper implementation, companies can effortlessly identify the quickest route for goods delivery and conserve fuel costs. This approach is cost-effective for both the logistics company and customers, as it helps avoid excessive shipping charges.

Delivery delays remain the biggest issue for both service providers and customers today. Factors such as weather conditions, factory closures, port capacity problems, or other disruptive events may slow down or even halt product delivery.

However, a logistics management system simplifies the automation of your delivery processes and enhances efficiency. It provides timely updates on product movement using tracking software or real-time shipment visibility.

This offers a comprehensive view of when the goods are dispatched, procured, and expected to be delivered. Automation eliminates the time wasted in manual operations and provides precise data and tracking, thereby improving the overall delivery process.

The logistics industry often faces issues stemming from its fragmented and inconsistent nature. The logistics supply chain involves various stakeholders - manufacturers, warehouse operators, drivers, managers, and customers- making centralized communication a challenge.

These problems can be mitigated by implementing robust communication and real-time visibility software systems that can be seamlessly integrated into the warehouse management system, granting access to partners and clients. This ensures everyone is informed and has a clear view of the different stages of production and distribution.

Sudden increases in demand or panic buying can affect inventory levels, customer satisfaction, and the entire supply chain. Timely product restocking is a significant operation that necessitates careful planning.

Accurate forecasting and automation can provide a comprehensive overview of inventory stock and help manage constant demand changes.

A logistics management system can effectively and flawlessly manage these operations to accommodate increasing delivery volumes and maintain customer satisfaction.

Common errors in warehouse management include misplaced items, incorrect packing or shipping, incomplete orders, or items damaged during delivery. If not controlled, these human errors can become expensive.

Using an efficient and up-to-date warehouse management system is the optimal way to minimize such errors. Logistics companies should invest in cutting-edge technologies like artificial and augmented intelligence, advanced analytics, automation, and warehouse robotics to manage their inventory, enhance business scalability, and gain a competitive advantage.

If you’re planning to choose a third-party logistics management system for your business, it is imperative to ensure you get the best one. Here are some factors to consider when selecting the best logistics management system:

Prior to choosing a logistics software solution, it's essential to identify the tasks you wish to automate or simplify and ensure that the software's capabilities align with these requirements.

As your business expands, your logistics management system should be able to scale with it. The software should be able to accommodate growth in terms of volume, product range, and geographical reach.

Check if the logistics software can seamlessly integrate with your existing systems, such as accounting or CRM software. This integration is vital for the smooth operation of your business processes.

The logistics software should be adaptable and customizable to fit your business operations. Software with a modular design is beneficial as it allows you to choose only the modules you require and integrate them effortlessly with other platforms.

At the same time, the system should allow you to switch between carriers easily. This feature enables you to select the carrier offering the most competitive shipping rates and delivery schedules.

It's crucial to have a transportation management system that offers live tracking of your entire supply chain, from your suppliers to your customers.

This real-time visibility can help reduce delivery times, pinpoint slowdowns, streamline operations, and keep your customers informed about their goods' whereabouts.

The system should be capable of monitoring your business's performance, creating tailored reports, and providing insights into key metrics such as stock levels, shipping costs, and delivery durations. This data can help you pinpoint cost reduction and customer service enhancement opportunities.

Strong security measures are essential to safeguarding your and your clients' data. Seek a logistics management system that adheres to industry security standards like PCI-DSS or ISO 27001. Consider using a decentralized public system like blockchain to secure the recording of all changes to logistics documentation.

Finding a third-party logistics solution that meets all your needs can be challenging, especially if your business requirements are ever-changing.

Creating your own logistics management system provides more flexibility, easier customization, and superior integration with other software. However, this approach may involve higher initial costs, more time, and the need for a trustworthy partner. Fortunately, Mtoag Technologies is here to help you.

Now that you have understood what a logistics management system (LMS) is and how it can benefit your business.

Start with brainstorming sessions to set the project's scope and goals. Without a clear objective, creating something that will deliver the anticipated outcomes is challenging.

Ascertain what you aim to accomplish with the logistics management system. Recognize your needs to incorporate the appropriate features into your LMS. Here are some common goals that companies often strive to achieve with an LMS:

An LMS can offer various interfaces for different users, such as managers, delivery personnel, suppliers, etc. These users can use the system to access or input information.

The development of custom software to oversee logistics processes involves numerous complexities. You require a team of experts who can professionally manage the project and develop the right solution for your business.

To create an LMS, you need various specialists like a project manager, business analyst, UI/UX designer, developers (frontend and backend), and quality assurance experts.

However, forming an in-house team might not always be practical, considering its high cost, as you'll have to cover overhead expenses and benefits.

On the other hand, outsourcing the software development project to companies like Mtoag Technologies seems a viable option because you only pay for the resources you utilize and avoid extra costs like salaries and office rent.

Now comes the most crucial part - the development itself. It involves a Business Analyst (BA) defining the project's scope and analyzing the necessary requirements to devise the optimal solution.

The Project Manager then outlines a roadmap for the development team, breaking down the project into manageable tasks to be executed in sprints. This allows the development team to work according to the roadmap and the scope outlined by the BA.

UI/UX designers craft the product's design, while the design and development team collaborates to create a software prototype that encapsulates the core functionalities.

The front-end developers implement the product's user interface. Conversely, the back-end comprises server coding, APIs, payment gateway integration, and more.

The development of a logistics management system requires different technologies for front-end and back-end development. Here's a look at the tech stack for a logistics management system:

Front-end Development

Back-end Development

Server

Database

Payment System

Notification System

Mapping

Mobile App Development

Following the development phase, the developed system undergoes a rigorous QA process. Engineers conduct comprehensive testing to identify and rectify errors, ensuring seamless operation. Once the QA team gives the go-ahead, the solution is ready to be deployed either on your local server or on the cloud.

With customers demanding fast deliveries, it has become a need for companies to focus on enhancing their logistics capabilities. To keep up with the customer’s demands, businesses need a reliable logistics management system that can help streamline their logistics operations. Ultimately, these systems can help companies to manage inventories and reduce storage and transportation.

If you’re keen to have a logistics management system for your business, Mtoag Technologies can help you do so easily and affordably. Contact us now to learn more about logistics software development.

Logistics Management is the process of overseeing the movement of goods from their origin to their final destination. For instance, if a shipment of dairy products arrives spoiled because refrigeration failed, that’s on the logistics team, not on production.

There are four main types of Logistics Management: Inbound Logistics, Outbound Logistics, Reverse Logistics, and Third-Party Logistics. Each type plays a pivotal role in creating an efficient supply chain.

Transportation, warehousing, and inventory management are the three major activities critical to the success of logistics operations. These functions ensure the timely and cost-effective delivery of goods to customers.

The 5 P's of Logistics are Planning, Procurement, Production, Placement, and performance. These principles guide logistics management and ensure the efficient movement of goods and resources across supply chains.